Fernando Gabriel S. Araujo

Federal University of Ouro Preto, Brazil

Title: Structural ceramics produced from soapstone tailings

Biography

Biography: Fernando Gabriel S. Araujo

Abstract

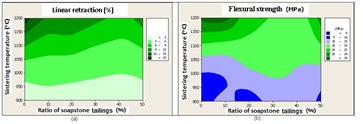

Steatite, commonly known as soapstone, is a rock of metamorphic origin, which has talc, a phillosilicate of hydrated magnesium, as its main component. The uses of soapstone are as natural stones for countertops, vanities, flooring and entryways, but the main applications are related to high temperatura uses, as fireplaces, stove countertops and kitchenware, besides its vast use in art, for the production of scultures. In Brazil, Minas Gerais state is by far the largest producer of soapstone and it has tradition both in exporting plates and blocks of the material to the whole world, and in producing sculptures and art in soapstone, since the collonial times, in the XVII Century. One oustanding fact is that the statue of Christ the Redeemer, one of the most famous symbols of Brazil, is covered with a soapstone layer. The processing of soapstone for the production of blocks and plates involves basically cutting by abrasion, and operation that, in the case of plates, results in a volume of rejects of up to 20% of the volume of production, consisting of fine grained soapstone. The aim of this work is to find a destination for this type of reject, as the use of tailings for the synthesis of new materials is a worldwide trend today. This paper approaches the utilization of tailings of soapstone (steatite) in order to produce ceramics. The experiments involved chemical, mineralogical and granulometric characterization of the rejects, followed by the production of ceramics with sopstone rejects additions, and the determination of the mechanical properties of the ceramics and their colors. The results show that the addition of soapstone in a ratio over 20% in the ceramic mass can enhance the bending resistance of the ceramic samples when they are fired at temperatures in excess of 900°C.