M Hesham El Naggar

Western University, Canada

Title: Use of Treated Oil Sand Waste in Cementitious Materials for Geotechnical Applications

Biography

Biography: M Hesham El Naggar

Abstract

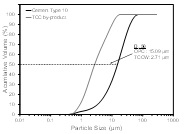

Oil sand drill cuttings waste is a major challenge for the oil sand mining sector. Many technologies have been developed to treat these cuttings and reduce the amount of waste to be landfilled. One of the recent technologies is Thermo-Mechanical Cuttings Cleaner (TCC), which separates water and oil from the solid waste1. The remaining part of the tailing is fine particles of mainly quartz crystals, which is referred herein as Treated Oil Sand Waste (TOSW). The present work offers innovative solutions for recycling TOSW in cementitious materials manufacture for geotechnical applications, and eventually other applications. The physical, chemical and mineralogical characteristics of the treated oil sand drill cuttings waste were investigated. Fresh and hardened properties for grouts2, concrete and controlled low strength material (CLSM)3 incorporating the treated oil sand drill cuttings waste were evaluated. The results showed that TOSW can be used as partial replacement of cement or sand, or full replacement of fly ash. For example, TOSW was used to replace up to 20% of cement in manufacture of grout used for constructing micropiles without adversely affecting the properties of the grout4. Similarly, TOSW can be incorporated in CLSM as a partial replacement of sand or full replacement of fly ash in CLSM to improve its important fresh properties such as flowability, while satisfying the density, strength and stiffness requirements for CLSM with no environmental hazards. Leaching tests evidenced the reduction in the release of heavy metals compared to that of raw waste indicating successful stabilization/solidification of such waste in the grout or CLSM. Furthermore, TOSW was incorporated into concrete mixture for continuous flight auger (CFA) piles as a partial replacement of up to 30% of natural sand5. It was demonstrated that concrete mixtures incorporating TOSW meet all the performance and environmental requirements of CFA concrete mixtures.