Judith Buchmaier

AEE – Institute for Sustainable Technologies, Austria

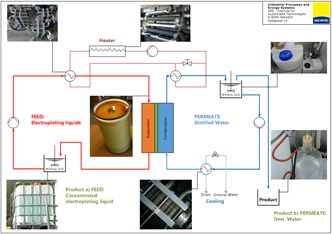

Title: Membrane distillation for energy-efficient treatment (concentration) of electroplating liquids

Biography

Biography: Judith Buchmaier

Abstract

In the electroplating industry there are processing steps which are very energy- and resource- intensive. An example is the rinsing of the products after the electroplating or etching bath. This can be done directly above the bath or in a separate basin. The rinsing leads on the one hand to the necessity of concentrating the electroplating or etching bath. On the other hand the rinsing water has to be treated in a way, that the electroplating substances are concentrated and can be returned to the bath and furthermore can be “cleaned” of the electro-plating substances for reusing it as water. Within the scope of this work the capability of the membrane distillation as application for the waste water treatment in the electroplating industry was tested. In order to analyze the membrane distillation under realistic operating conditions, experiments were carried out at a membrane distillation plant installed at an electroplating company. During the experiments, the operational capability of the membrane distillation for use in treatment of electroplating liquids was tested in a first step. Furthermore experiments for reaching required concentrations of bath ingredients were conducted. All in all the experimental investigation showed the feasibility of treating electroplating liquids through membrane distillation. Through the experiments the electroplating substances were concentrated and the fresh rinsing water was prepared for reusing it in the rinsing bath.