Day :

- Industrial Waste Recycling | Waste Management Techniques | Waste Water Recycling | Rubber Recycling | Recycling Basics | Textile Recycling | Agricultural Waste Recycling

Session Introduction

E. David

National Institute for Cryogenic and Isotopic Technologies, Romania

Title: Recycling approaches of the aluminum dross to obtain useful products and to preserve raw material sources

Time : 11:20-11:45

Biography:

E David is a graduate from Faculty of Chemistry and Chemical Engineering and did MS in Physical Chemistry in Surface and Analytical Chemistry from Babes- Bolyai University, Romania. She serves as a Doctor of Chemical Science, Assoc. Prof. and Head of Department of Carbonic Materials, Composites & Analysis Techniques at National Research Institute of Cryogenics & Isotopic Technologies, Romania. She is author of more than 20 inventions in the field of environment, energy, waste recycling, and materials. The World Intellectual Property Organization (WIPO) awarded her the WIPO prize, both at the International Exhibition of Inventions in Geneva, Switzerland in April 2012 and in Brussels, Belgium in November 2014, for two inventions in the field of Waste Recycling and Clean Energy. She held over 80 lectures at national and international scientific conferences and congresses and has published over 140 scientific papers in prestigious national and international publications. She is Member of the World Academy of Materials and Manufacturing Engineering, Physical European Society and Association of Computational Materials Science and Surface Engineering, Poland. She acts as Reviewer for prestigious international journals like Journal of Materials Processing Technology, Journal of International Hydrogen Energy, Journal of Hazardous Materials, and more. ele

Abstract:

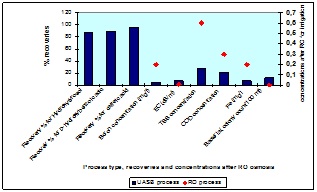

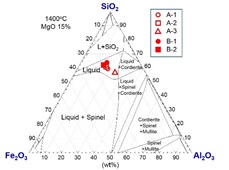

The aim of this research is to answer the challenge of how a hazardous waste can be transformed into raw material source, presenting the particular case of a solid aluminum residue, such as aluminum dross. In this waste, it is included as fine fraction of less than 50 μm; and this waste is considered as a hazardous aluminum waste, among other reasons, because of its poor chemical stability, its spontaneous and exothermic reactivity with water and environmental humidity, generating hydrogen, ammonia, methane, hydrogen sulphide, phosphine, etc. The presence of these phases in the aluminum dross depends on the type of furnace used and above all on the atmosphere inside the furnace, together with the type and quality of the scrap used in each installation. In the first part of this paper, the physico-chemical characteristics and what is the negative impact on the environment and people health of the aluminum hazardous waste, if this is stored in landfill, is presented. Then, some examples of our achievements of how this waste can become a useful raw material for obtaining high value added products, how would be to generate hydrogen as a source of clean energy, getting boehmite, alumina and a harmless environmental residue, is shown. Further, for the development of aluminum dross recycling process, a study on aqueous leaching can offer a new and very interesting economic way. A major problem is the reaction between the AlN amount from the slag and water (vapor or liquid phase), which can produce NH3 gas emission, representing a serious environmental hazard. In the second part of this paper, a leaching process, using water saturated with CO2, is attempted with the aim to retain in situ the ammonia by absorption. The laboratory experimental results highlight that the extraction of K and Na salts from the slag are high (>95 wt% ) at a solid slag mass to liquid water ratio of 1:25 and 3 hours of leashing, at room temperature. Also, with a continuous CO2 bubbling at a maximum flow rate of 60 ml/min, the amount of NH3 gas releasing has decreased from 0.3624 mg/l water to <0.0065 mg/l, highlighting the effectiveness of the NH3 absorption in carbonized water (>97%). By comparison with the results obtained during leaching experiments using pure AlN, this shows that the introduction of CO2 is an impediment to the hydrolysis of AlN. The retention of AlN into the leach residue and the leaching only of the salt cake by carbonated water becomes a promising way towards removal and recovery of the salts from aluminum dross and towards the obtaining from the leach residues of the aluminum oxynitride (AlON), a material with very good ceramic characteristics.

Marina Zoccola

Italian National Research Council, Italy

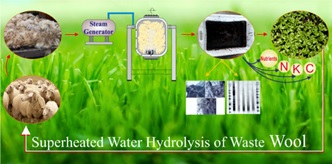

Title: Green hydrolysis conversion of wool wastes into organic nitrogen fertilisers

Time : 11:45-12:10

Biography:

Marina Zoccola has been working since 1989 as a researcher at the National Research Council, Institute for Macromolecular Studies, textile section of Biella. Her principal interests are in the study and characterisation of biopolymers, mainly structural proteins (wool, fine animal fibres, silk, human hair). She has participated in national and international research projects in the textile and biopolymer field. She was author of over 30 scientific works published in international journals.

Abstract:

The European Union (EU) area has the second largest world sheep population, numbered to about 87 millions (Source EU-Eurostat 2014). The EU flock is made of crossbred sheep not graded for fine wool production. The annual wool clip amounts to about 200 000 t and its management is a specific problem for the EU livestock sector. Indeed, wool from sheep farming and butchery industry is very coarse and contains a lot of kemps (dead fibres), making it practically unserviceable for the textile industry. Unserviceable wool is mostly disposed in landfills or illegally thrown over. Thus, shearing, storage, transportation and disposal of waste wool in accordance with current EU Regulation, heavily weigh on the profit of sheep farming. The Life+ 12 ENV/IT000439 GreenWoolF project aims at converting waste wool into nitrogen fertilizers at a commercial scale for grassland management and organic agriculture purposes. The chemical transformation is based on a green economically sustainable hydrolysis treatment using superheated water. The experiments were carried out in a semi-industrial reactor feeding superheated water and, due to condensation, the wool/superheated water system was maintained for different reaction times. The optimal conditions for this treatment were: 170 oC for 60 min with a solid to liquor ratio close to 1. Chemical analyses such as amino acid analysis and molecular weight distribution performed on the hydrolysis products obtained revealed that the wool was completely degraded, the reaction product containing low molecular weight proteins and amino acids. Several product batches tested for germination showed an index higher than 100% without collateral phytotoxicity. The presence of amino acids, primary nutrients and micronutrients in wool hydrolyzates, along with a concentration of heavy metals below the standard limit, confirms the possibility of using wool hydrolyzates as nitrogen based ecologically sound fertilizer suitable for organic agriculture.

Pelin Alicanoglu

Pamukkale University, Turkey

Title: Photodegradation of Levofloxacin Antibiotic via Graphene/TiO2 and Its Reusability

Time : 12:10-12:35

Biography:

Pelin Alicanoglu is a PhD candidate at Pamukkale University. Pelin completed her Master Degree at Dokuz Eylül University. She has expertise on wastewater treatment, advanced oxidation processes, micropollutant removal and nanotechnology. Currently, she is research assistant at Pamukkale University.

Abstract:

Antibiotics are extensively being used in our lives for human disease treatment, aquaculture, and livestock operations. Due to the inappropriate wastewater disposal practices, a portion of the antibiotics are discharged into the environment in their original or metabolized forms [1]. Levofloxacin (LEV) is a more recently developed antibiotic belonging to the fluoroquinolones (FQs) which are synthetic broad spectrum antibiotics and is the optical S-(-) isomer of ofloxacin [2]. However, it is difficult to remove LEV from wastewater through traditional biological methods because of its toxicity and low biodegradability [2]. Graphene oxide (GO) is hydrophilic due to the oxygen-containing functional groups on its surface, which renders GO sheet a good candidate for supporting nanoparticles in liquid phase [3]. TiO2 could produce powerful oxidants capable to degrade organic pollutants until total mineralization [4]. Semiconductor materials have been widely studied and used in the fields of pollutant degradation due to their environment friendliness [3]. The aim of the present work was to synthesize a new nanoparticle (G-TiO2) and remove LEV antibiotic from synthetic wastewater at different operational conditions. In order to determine the maximum photodegradation yields of LEV with G-TiO2 composite, the effects of increasing LEV concentrations (1, 5, 25 and 100 mg/L), increasing irradiation times (15, 30, 45, 60 and 120 min), increasing G-TiO2 concentrations (0.1, 0.25, 0.5, 1 and 2 g/L) and different pH levels (4, 7 and 10) were researched. The maximum removal efficiency of LEV (for 1 mg/L) was obtained as 97% {G-TiO2 concentration: 0.25 g/L, pH: 7, temperature: 21°C, UV power: 300 W, irradiation time: 45 min}. Moreover, six sequential treatment steps were investigated for determination of reusability of G-TiO2 composite. The photocatalytic degradation percentage was reduced from 97% to 74% on first cycle to sixth cycle.

Hyokwan Bae

Pusan National University, Busan, South Korea

Title: Membrane-based dewatering processes using FO and MD for nitrogen recovery from wastewater

Time : 12:35-13:00

Biography:

Hyokwan Bae has been working at Korea Institute of Science and Technology as a Research Scientist for 11 years (2006-2017). He participated in a number of research projects on nitrogen removal, membrane separation, biofilm and culture-independent analysis of bacterial community structure. After obtaining a PhD degree in Interdisciplinary Program of Bioengineering at Seoul National University in early 2014, his research has been concentrated on the integration of biological reaction and membrane separation processes linked to obtaining high quality reclaimed water and resource recovery (e.g., partial nitrification, halophilic bacteria, forward osmosis, membrane distillation and fouling control). Recently, he joined the Faculty of Pusan National University in 2017 to broaden and improve his specialty in Civil and Environmental Engineering.

Abstract:

Forward osmosis (FO) and biological nitrification processes were integrated in this study. High strength ammonia wastewater of 2500 mg-N/L was partially nitrified at an ammonia conversion rate of 1.34 ± 0.25 kg-N/m3-day under the limitation of an acidification buffer, i.e., HCO3–-C/NH4+-N = 1, as a control factor. To mitigate the membrane fouling, direct contact between the biomass and cellulose triacetate FO membrane was avoided by employing PVA/alginate-immobilized nitrifiers in the bioreactor. The simultaneous FO process concentrated the wastewater at concentration factors (CFs) of up to 2.34 during the partial nitritation (PN) reaction. As a result, the concentration of total dissolved solids (TDS) ranged from 13.6 g/L to 35.7 g/L. It was found that salinity higher than 17 g-TDS/L inhibited the activity of the nitrite-oxidizing bacteria, but not the ammonia-oxidizing bacteria. Then, the nitrogen content of wastewater was further concentrated using direct contact membrane distillation (DCMD). The ratio of transferred ammonia to water (i.e., speciï¬c ammonia transfer: SAT) was controlled by operational conditions of membrane materials, pH and temperature. It was identified that free ammonia (FA) concentration has a critical role on SAT values under different total ammoniacal nitrogen concentration and pH. Thus, the acidiï¬cation pretreatment was essential to minimize the FA concentration in the feed before operating the DCMD system. Taken together, membrane-based dewatering processes were effective to reduce the water contents in the wastewater and the remained nitrogen contents can be utilized as a concentrated fertilizer.

Handan AKÃœLKER

Ondokuz Mayıs University, Turkey

Title: Full factorial design to removal of Zinc (II) ions from water by using hydrogel microspheres

Time : 13:45-14:10

Biography:

Handan Akülker graduated from Chemical Engineering and Genetics. Bioengineering double major program at Yeditepe University with full-scholarship in 2012. She worked at State Hydraulic Works as an analyst for 3 years. Then, she started to work as a research assistant at Ondokuz Mayıs University in 2016. She is still a master student at Chemical Engineering Department.

Abstract:

Zinc is one of the most plentiful elements in the Earth. Its concentration both in soil and water is increasing because of industrial activities, such as mining, coal and waste combustion and steel processing. Despite being handled by humans, too much of it can still pose fatal diseases. Therefore, Zinc is studied to be removed from water by using several methods. With respect to recent studies, Alginate has been suggested to be harmless to both environment and human health due to its biodegradable composition. Hence, it is widely used in adsorption processes. The aim of the study was to remove Zinc (II) ions from water by using Ca-Alginate microspheres and also to design the adsorption by full factorial method. Na-Alginate and CaCl2 were used to synthesize Ca-Alginate hydrogel microspheres with approximately 4 mm diameter in wet form. Microspheres were chosen to be synthesized instead of gel form in that their high surface area per their small weight could boost the efficiency of adsorption. In order to determine the significant parameters of adsorption, 23 full factorial design was performed. The combined effects of adsorbent dosage on, temperature during adsorption and initial concentration of water were examined. For three parameters, minimum and maximum values were determined to be performed. According to these values, eight experiment sets were carried out. The results of these experiments were statistically analyzed by using the student’s t-test, analysis of variance (ANOVA) and an F-test to define important experimental factors and their levels. A regression model considering the significant main and interaction effects was suggested. In conclusion, using Ca-Alginate hydrogel microspheres can be plausible and environmentally friendly method for adsorption of Zinc from water.

Katarzyna Kulhawik

Poznań University, Poland

Title: Direct landfill disposal versus Mechanical-Biological Treatment (MBT)

Time : 14:10-14:35

Biography:

Katarzyna Kulhawik has graduated from 5- year master’s degree studies in the field of Environmental Protection of PoznaÅ„ University in Poland. She so much interested in environmental protection that she has started postgraduate extramural studies (doctoral). Her speciality is environmental protection including waste management. The topic of her research is the functioning of recycling in the system of waste management based on the example of the district of GÅ‚ogów. Besides scientific activity she train workers in the field of waste management

Abstract:

After the implementation of a new waste management system, in which recycling is the most dominating process, landfill disposal still appears to be the most popular method of waste management in Poland. In which waste undergoes gradual decomposition and the influence of climate conditions, for example, air and atmospheric fallout, leads to the production of leachate and biogas emissions, which contribute to continual threats to the natural environment and humans. The above-mentioned threats can be limited by applying suitable techniques of waste treatment before its disposal. A technology that is oriented to these aims is a mechanical biological treatment. The results of this technology is waste stabilisation and reduction of pollutant emissions. Additionally, it allows to increase the recovery of materials for recycling and to reduce the mass of waste ( it is environmentally friendly). Finally will be described differences (advantages disadvantages) between direct disposal versus mechanical- biological treatment.

Huseyin Koca

Anadolu University, Turkey

Title: Recent developments in management of energy plants’ wastes

Time : 14:35-15:00

Biography:

Huseyin Koca completed his undergraduate education at Anadolu University, Eskisehir, Turkey, and went on to obtain an M.Phil. degree from Leeds University, England. He obtained his Ph.D. from Eskisehir Osmangazi University, Turkey. Currently, he is professor at Anadolu University, Eskisehir, Turkey

Abstract:

The share of electricity production by means of coal fired power plants is over 40% in the World. A large quantity of solid waste are produced each year due to the high ash content of coals. It is estimated that over 750 million tons of coal combustion products, fly ash, bottom ash, boiler slag and flue gas desulphurization gypsum, are produced annually in all over the World. Approximately half of these material are recycled or reused as a raw material in cement and construction materials, ceramic making, and extraction of valuable minerals … etc. The rest is simply discarded to landfills that causes severe environmental problems. The European legislative frame work has forced the EU Member States to introduce a waste prevention programme since 2013. They either integrated into their own waste prevention programmes or other environmental policy programmes or established as a standalone programme. Waste prevention programme should describe a minimum waste prevention objectives and implement other preventive measures. The EU’s approach to waste management is based on four principles: waste hierarchy, precautionary principle, principles of polluter pays and producer responsibility and principles of proximity and self-sufficiency. These principles have key roles to achieve sustainable waste management system and environmental protection. In this work recent developments in management of energy plants’ wastes were investigated.

Evangelia Karvela

Yiotis S A, Greece

Title: Development of an integrated strategy for reducing the carbon footprint in the industry sector

Time : 15:00-15:25

Biography:

Evangelia Karvela is a Food Technologist with a PhD degree in winery byproducts and their use as food additives due to their antioxidants effect. The last 5 years, she has been working at Yiotis Company in R&D departments. She has more than 10 publications, participated in international conferences and she collaborates with Harokopio University as a Researcher. The main aim of her job is how different by-products could be treated and incorporated in foods, giving an additive nutritional value in the final product, reducing at the same time the amount of the food industry wastes.

Abstract:

Statement of the Problem: The food industry is a major emitter of CO2, which is produced during the stages of food processing, storage and transportation. The LIFE FOODPRINT project’s main goal is to identify, quantify and implement measures to reduce the carbon footprint (CF) of the pastry and flour industry sector along the supply chain while increasing competitiveness through the development of an innovative software tool. Methodology & Theoretical Orientation: National Technical University of Athens (NTUA) has developed an interactive software tool which can determine and evaluate the CF of pastry and flour food product considering direct and indirect activities (energy consumption, water, waste water, etc.) using data from six food industries (production, distribution, storage/warehouse, organic cleaning company). Yiotis S.A. from Greece has been used along with other industry players in Italy AB Mauri and Molino, as case studies, in which different measurements were held such as evaluating the products’ CF along the supply chain, identifying the carbon hotspots contributing in raising the products’ CF along the value chain and developing GHGs emissions mitigation programs for the participating food industries by incorporating appropriate set of offsetting measures. The software was evaluated and further improved by using it and performing further measurements in 6 more pastry and flour industries in Greece and Italy. The main unresolved issue as environmental contaminant so far, is packaging, for which the only solution so far is the recycling. A biodegradable packaging material has been developed and printed in the original way demonstrating an attractive film similar to the normal plastic materials; extensive study is underway to determine migration of contaminants from ink, glue and plasticizers. When this is confirmed there will be huge impact on the environment. Results: Yiotis S.A. achieved a 10-15% reduction of CO2 emissions. The biodegradable material is almost ready to be tested in its primary and colorful edition. The program is currently being disseminated. A leaflet is under preparation to accompany various products of Yiotis and inform consumers regarding FOODPRINT program, as well as the product manufacture’s GHG emissions. Conclusion & Significance: Through LIFE FOODPRINT Yiotis S.A., in collaboration with SEVT, tries to develop a national recommendation plan considering the reduction of GHG emissions of pastry and flour food industries in Greece and Italy and increase their competences in the future.

Judith Buchmaier

AEE – Institute for Sustainable Technologies, Austria

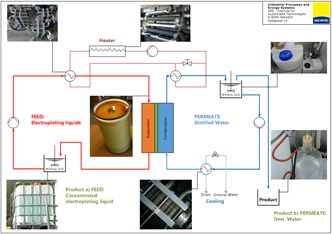

Title: Membrane distillation for energy-efficient treatment (concentration) of electroplating liquids

Time : 15:40-16:05

Biography:

Judith Buchmaier has studied technical chemistry and biotechnologies. She is now working on thermal separation technologies. Her expertise lies in different applications of membrane distillation. Her studies include membrane stability tests, test cell experiments such as execution of experiments in pilot scale. Among other applications such as ammonia recovery from biogas sludge, waste water treatment with membrane distillation one focus area lies in the optimization and recovery of valuable substances in galvanizing and printed circuit board industry

Abstract:

In the electroplating industry there are processing steps which are very energy- and resource- intensive. An example is the rinsing of the products after the electroplating or etching bath. This can be done directly above the bath or in a separate basin. The rinsing leads on the one hand to the necessity of concentrating the electroplating or etching bath. On the other hand the rinsing water has to be treated in a way, that the electroplating substances are concentrated and can be returned to the bath and furthermore can be “cleaned” of the electro-plating substances for reusing it as water. Within the scope of this work the capability of the membrane distillation as application for the waste water treatment in the electroplating industry was tested. In order to analyze the membrane distillation under realistic operating conditions, experiments were carried out at a membrane distillation plant installed at an electroplating company. During the experiments, the operational capability of the membrane distillation for use in treatment of electroplating liquids was tested in a first step. Furthermore experiments for reaching required concentrations of bath ingredients were conducted. All in all the experimental investigation showed the feasibility of treating electroplating liquids through membrane distillation. Through the experiments the electroplating substances were concentrated and the fresh rinsing water was prepared for reusing it in the rinsing bath.

Szymon Wojciechowski

Szymon Wojciechowski, Silesian, University of Technology, Poland

Title: Multimaterial laminated film recycling – PE-Al, PE-PA and PE-PET full material recovery without downcycling

Biography:

Szymon Wojciechowski has his expertise in multi-material laminates recycling using solvent extraction as the main method. His work is focused on overcoming major obstacles that now prevent wider commercialization of multi-material waste recycling without material quality degradation

Abstract:

Multimaterial waste is a difficult material to recycle. In terms of laminated film processing, this issue is even more apparent, as mechanical separation of the base materials is not possible. There are very few technologies able to process the most common laminates used in food packaging such as PE-PET, PE-PA and PE-Al. Many of such process are either based on energy recovery or offer products of low quality (downcycling). Multi-material laminates when recovered from communal waste are mixed with other polymers and contaminants. On the other hand, output of postproduction waste with manageable levels of contamination is growing every year. New advanced technologies enabling a full material recycling of waste laminates are in their early stages of implementation. Processes based on chemical delamination or polyethylene dissolution/extraction enable to obtain products with virgin like properties, but will high quality of recycled products justify intense energy consumption and investment cost?

Handan AKÃœLKER

Ondokuz Mayıs University, Turkey

Title: Color removal from textile dyeing effluent by natural and activated clay adsorbents

Biography:

Handan Akülker graduated from Chemical Engineering and Genetics. Bioengineering double major program at Yeditepe University with full-scholarship in 2012. She worked at State Hydraulic Works as an analyst for 3 years. Then, she started to work as a research assistant at Ondokuz Mayıs University in 2016. She is still a master student at Chemical Engineering Department.

Abstract:

Colored organic effluents are produced in different industries, i.e. textiles, paper, leather, plastics, rubber, cosmetics etc. Discharging of dye effluents into water resources even in a small amount can affect the aquatic life. Dye ions are commonly removed from aqueous streams through coagulation-precipitation, ion exchange, ultrafiltration, nanofiltration, reverse osmosis, electro dialysis and solvent extraction. These methods are expensive. Adsorption is the most popular method for wastewater treatment due to its easy and inexpensive operation. In this study removal of malachite green dye ions from aqueous solutions using natural and activated clay adsorbents was studied. The effects of contact time, initial dye concentration and adsorbent dosage on malachite green dye removal efficiency were examined in a batch system. The equilibrium adsorption data were analyzed by Langmuir, Freundlich and Temkin adsorption isotherm models. The pseudo-second order, Elovich and intraparticle diffusion kinetic models were applied to the experimental data in order to describe the removal mechanism of dye ions using natural and activated montmorillonite clay. The results show that natural and activated montmorillonite is an alternative low-cost adsorbent for removing malachite dye ions.

Muhammad Rusdy

Hasanuddin University, Indonesia

Title: Banana (Musa sp) Wastes as Ruminant Feed

Time : 16:55-17:20

Biography:

Muhammad Rusdy, Faculty of Animal Science Hasanuddin University in Department of Forage Science and Grassland Management, Indonesia

Abstract:

Banana is a traditional plant cultivated for its fruit. After harvesting, the remaining plant parts, i.e. pseudo-stem, leaf and fruit peel that consisting of around 80% can be used as feed for ruminants, as they contain high amounts of nutrients. The highest crude protein content of banana wastes is found in the leaf, followed by fruit peel and pseudo-stem. Both banana pseudo-stem and leaf contain moderate amounts of fiber but are higher than that of banana peel. The high contents of tannin in the leaf and fruit peel reduced their protein and dry matter digestibility and their value as ruminants. The low crude protein and high moisture contents of pseudo-stem reduced dry matter intake potential by ruminants. Due to the low digestibility of leaf and fruit peel and the low dry matter and crude protein contents of stem, to obtain high animal production from ruminants fed banana wastes, it should be supplemented with proteinaceous and carbonaceous concentrate feeds.

Stephen W. Brooks

Federal Law Enforcement Training Centers, USA

Title: Sustainability can be profitable and profitability can be sustainable: Converting trash into valuable recyclable commodities

Biography:

Stephen W. Brooks is the Chief of the Assets and Logistics Management Division (ALM) of the Federal Law Enforcement Training Centers (FLETC) Glynco campus. As Chief of ALM he is responsible for all the personal property located at four FLETC sites. This includes 32,691 assets valued at $96,190,410.39 dollars located in Charleston South Carolina, Cheltenham, Maryland, and Artesia, New Mexico. He oversees the business lines of inventory management, Fleet management, mail management, property disposal, and the recycling program In 2015 he was named the “2015 Sustainability Hero” for the Department of Homeland Security (DHS) for his innovations in recycling solid waste generated by law enforcement firearms training. He has published in the area of recycling and is has been a noted speaker at the 2015 Southeastern Recycling Conference in San Destin, Florida and the 2015 Georgia Recycling Coalition Conference on St. Simons Island, Georgia.

Abstract:

Statement of the Problem: A common reason given for not recycling is that it is not cost effective and too costly to do. To be successful is easy but one has to shift paradigms to make it work. Whether you are an educational campus, training facility or community, it can be done effectively and efficiently. It will take a shift in culture and thinking in the beginning. That first shift is to stop thinking of all solid waste as “trash”, but rather a commodity that has monetary value in today’s market place of shrinking resources. Recyclable commodities such as old corrugated cardboard (OCC), standard office paper (SOP), aluminum drink cans are no different that gold, orange juice, or pork bellies, they are sold to those companies that need the recyclables as raw material to keep their mills operating, personnel employed, and their products flowing into the stream of commerce around the globe. These recyclable commodities are crucial to saving natural resources when they are processed back into their natural states to begin the manufacturing process all over again. Aluminum can be recycled indefinitely and results in a 95% energy savings and reduces pollution by 95% over tradition saves 4 lbs. of bauxite from being smelting for pound of aluminum recycled. Recycling not only generates positive revenue streams but also, saves natural resources, but also allows for cost avoidance associated with traditional waste collection and disposal.

Md. Abdul Jalil

Bangladesh University of Engineering and Technology, Bangladesh

Title: Investigation of Biogas Generation from the Waste of a Vegetable and Cattle Market of Bangladesh

Biography:

Abstract:

The results of a study on the type and quantity of solid waste generated in a rural vegetable and cattle market, and biogas generation from the waste are presented in this paper. The market waste was collected, individual items were separated and measured on both normal days and haat days. During a normal day, it was found that very insignificant amount of waste was generated. But on a haat day, a large amount of wastes was found to be generated. On average, the amount of easily biodegradable waste was 589 kg out of the total waste of 1004 kg on a haat day. Cow dung, fish, ginger, cursed lobe, guava and banana leaves were the major biodegradable wastes. Other biodegradable wastes were goat dropping, bitter melon, pointed gourd, dhundul and brinjal. The total solids (TS) and volatile solids (VS) of the biodegradable portion of the market waste were determined and were found to be 17.94% and 13.87% respectively. Laboratory experiments were run order to generate biogas in anaerobic digesters using the same composition of the market waste. They were placed in a large closed chamber and room heaters were used to maintain the temperature of the chamber at a constant value. One set of batch experiments and another set of daily feed experiments were carried out. In the first set of experiments, 500 g and 750 g waste added in 2 digesters separately and inoculum was added to make the effective volume of 2.1 L for each digester. The experiments were operated for 46 days and the average temperature was found to be 34.7oC. In the second set of experiments, one digester was initially fed with 750 g waste having the effective volume of 2.2 L. Another two-chamber (connected in series) digester was initially fed with 750 g waste having the effective volume of 3 L. Then the daily feed was 18.75 g waste mixed with 20 mL of water with dispensing 40 mL slurry from the digester. The experiments were run for 40 days and the average temperature was 35.1oC. The results of the 1st set of experiments revealed that the daily biogas generation rates were 0..22 and 0.48 m3/m3 of digester volume for the concentrations of waste as 0.238 and 0.357 kg/L respectively for 40 days retention time, and the respective rates of biogas producton were 0.30 and 0.40 m3/kg of VS added. The results of the 2nd set of experments revealed that the daily production of biogas was 0.44 and 0.37m3/m3 of the digester volume for the one-chamber digester and two-chamber digester respectively. But in terms of per kg VS added, the average daily gas generation rates were 0.185 m3 and 0.212 m3 for the respective digesters.

Diego Piazza

University of Caxias do Sul, Brazil

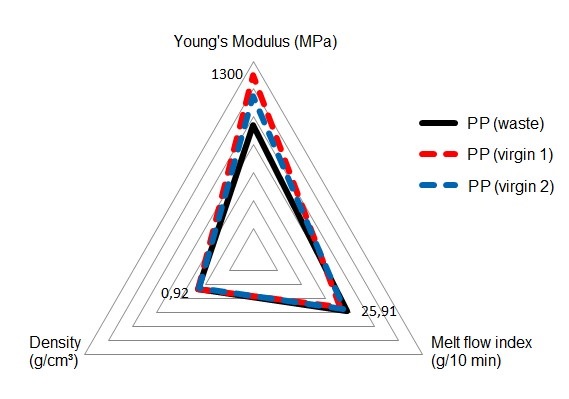

Title: Recyclability of polypropylene (PP) and polyethylene (PE) waste from the Hawaii coastline

Biography:

Diego Piazza has graduation at Tecnologia em Polímeros from Universidade de Caxias do Sul (2007), master's at Engenharia e Ciência dos Materiais from Universidade de Caxias do Sul (2011) and doctorate at Engineering from Universidade Federal do Rio Grande do Sul (2016). He is currently professor mestre (assistente) nível ii at Universidade de Caxias do Sul. He is currently a professor at the University of Caxias do Sul and has held the position of coordinator of the Polymer Technology Undergraduate Course at UCS from 2011 to 2016. He works in the field of polymer nanocomposites, coatings, materials recycling and the processing of polymeric materials by Injection, extrusion, thermoforming and rotomoulding. Participates in the UCS Entrepreneurship program. Integrates the group of researchers with The Ocean Cleanup (Holland) in the study of degradation and recovery of polymers from the marine environment. He has experience in the area of project development and research in the field of materials science and engineering, with emphasis on polymers, polymer materials processing, polymer nanocomposites, organic coatings, intelligent inks, powder paints, and materials recycling.

Abstract:

Introduction: One of the major environmental problems is the ocean pollution. It is estimated¹ that the oceans’ surface holds more than 13.000 polymer fragments/km2. These fragments harm the fauna, since animals’ mistake polymers for food leads to death nearly 100 thousand marine mammals every year2. Synthetic polymers are inert towards degradation, this way, the material tends to accumulate in the oceans as a result of the huge consumption of polymers. This work aims to develop a methodology to recycle polymers found in oceans, comparing their mechanical and rheological properties with virgin polymers.

Experimental :The polymers employed in this work were collected on the beach sand of Kamilo Beach, Hawaii with the help of the The Ocean Cleanup team. Among the collected polymers higher amounts of PE and PP is highlighted. After clean and dried, they were ground in a knife mill. The resulting product had an average particle size distribution of 2 cm and was separated according to different densities. Afterwards the polymers were extruded in a single-screw extruder at the temperature profile of 170/185/200°C for PE and 180/195/210°C for PP. Afterwards, test specimens were obtained by injection, and then submitted to the flexural strength (ASTM D790), and melt flow index (performed under 190°C, 5Kg and 20s for PE; 230°C, 2.16 kg and 10s for PP) tests.

Results: Data obtained for the modulus of elasticity and melt flow index for PP and PE waste had values close to those of the respective commercial virgin resins.

Conclusions Based on the obtained results it is concluded that although the polymers has been exposed to different weather conditions, PE and PP waste can be recycled and bear properties which enable them to be used in the production of new products

Daniela Gurau

Horia Hulubei National Institute of Physics and Nuclear Engineering, Romania

Title: Concept and regulations regarding the recycle of material that comes from the decommissioning of a nuclear research reactor

Biography:

Daniela Gurau has her expertise in laboratory and in-situ gamma-ray spectrometry measurements and analysis with different type of detectors, radioactive waste assay using complex systems, coincidence summing effects evaluation, detector characterization, Monte Carlo simulation of radiation transport. She started to work in the Radiological Characterization Laboratory from Reactor Decommissioning Department, IFIN-HH, in January 2006, and since then she contributed in the development of gamma-ray spectrometry techniques used in radiological characterization and free release of radioactive waste materials, combining experimental methods with theoretical and Monte Carlo simulation procedures. She has various scientific papers and contribution in important research projects.

Abstract:

A main aim of the decommissioning project from Magurele, Romania is to follow the standards and regulations to minimize the radiation doses and to limit the release of radioactive materials into the environment. Concerning the release of materials from the regulatory control, all the waste materials that comes from decommissioning practice are assumed to be radioactive even if the material has not come into contact with any radioactivity. Because of that, in order to protect the health against ionizing radiation, release of materials from regulatory control can be made only if these materials are “free of radioactivity”. Besides the disposal of radioactive waste, a parallel aspect is addressed by the national competent authorities that allow the materials that arise from radioactive practices to be released and reused or recycled if the radioactive content is in accordance with the release conditions. While clearance levels may very well be defined generically, the decision whether to apply clearance levels is an individual decision of the competent authorities on the basis of a case-by-case evaluation of the practice which gives rise to the contaminated or activated material. Direct and indirect measurements of surface contamination and measurement of activity using various gamma-ray spectrometry systems are used by the Radiological Characterization Laboratory to decide what will happen with the materials resulted from decommissioning. In Romania, all the solid materials that comes from nuclear facilities and meet the release criteria are sold for a profit. An innovative method for the recycle of the low level of radioactive concrete (contaminated or activated) has been developed by the Reactor Decommissioning Department from IFIN-HH, allowing to minimize the volume of the radioactive concrete that should be disposed.

Silvia Dalzero

Iuav University of Venice, Italy

Title: Rejected landscapes / recycled landscapes: waste disposal and recycling sites

Biography:

Silvia Dalzero has an architect since 2006 and a PHD in architecture with a thesis about urban transformations in relation to disposal systems waste. She obtained a reserch, at the University of Architecture in Venice, IUAV, in theme of ‘Ruins, debris and rubble in the theaters of war. From decontamination issues and disposal to the configuration of new landscapes’. She collaborates on the teaching at the IUAV in the course of Architectural-urban design (prof. Alberto Ferlenga). She was professor of Theory and practice of architecture (2012/2013), Architecture of the public space (2013/2014) at POLIMI and since 2014/2015 she is professor of Architectural-urban design (in Architectural design workshop 1), at University of Architecture in Milan, POLIMI. Than, She is professor at Academy of Art in the course of Design (in biennium of speciality). She has several publications including the monograph 'Rejected landscapes-Recycled landscapes. Waste disposal and recycling sites, perspectives and contemporary approaches' published in January 2015 by Scholars-press.

Abstract:

This article wants to show the landscape changes in the presence of waste, some touchable reality that invades the territory in many different ways in terms of time and space. Firstly, the issue of garbage is faced following its inevitable accumulation that designs our new and unexpected landscapes... secondly, the focus will be on how waste can be turned into a place. So, how through a list of projects for more or less controlled recovery altered areas, the present territorial dimension is inexorably besieged by garbage and consequently how it is exposed to a substantial environmental, cultural, economic and political alteration. Consequently a sort of ‘indicative atlas’ - where some interesting and reference recovery plans are illustrated - will be shaped. This perspective shows the present conditions and the effective distribution of plants for waste disposal and collection on the European territory in general, and more particularly in Italy: here the study becomes more detailed and a territorial section in Italy, Lombardy, is going to be analyzed. The territorial morphology and the inevitable environmental transformations are also taken into consideration. So, through a study of the present territorial conceptual status, indicative and synthetic models shape up from possible and potential scenarios of areas that are or will be altered in the future. The study of these areas make up a unique path to observe and evaluate the modern urban structure, where presently it is necessary to have a correct, definite location, leading to territorial changes in different ways. Furthermore, this research can contribute to give the right measure of what is at stake, that is different territorial status and other perspectives.

Stanislav Duev

Kazan National Reasearch Technological University, Russia

Title: Investigation Of The Multiplicity Of Steady States In The Recycle System: Reactor- Separation Unit

Biography:

Abstract:

An efficient way to solve the problem of minimizing chemical industrial wastes is recycling unreacted feed materials. For this purpose the reactor-separator recycle system can be used (Figure 1) However a feedback causes an appearance of multiplicity of the steady states in the reactor. A problem of the steady states multiplicity in chemical reactor has been examined for a long time by van Herden (Van Heerden,1953) and other. Also there are numerous articles in which the problem of the steady states multiplicity and stability of the reactor with recycle has been analysed (Luss and Amundson, 1967), (Kiss, Bildea, Dimian, Iedema and other). The existence of the finite set of steady states (odd number) in the reactor was indicated in all these works. But an appearance of qualitatively new properties in the reactor taking place in the recycle system: reactor – separating unit is possible. It is shown as an existence of continuum (infinite set) steady states in the reactor ( Boyarinov, and Duev, 1980, Boyarinov, and Duev, 2005, Duev and Boyarinov, 2010). Continuum of the steady states is possible to be only in recycle system for the operational mode with a complete utilization of feed and intermediate reactants.

Sandra R. Scagliusi

IPEN/CNEN, Brazil

Title: Butyl Rubber Recycling by means of gamma radiation followed by mechanical shear

Biography:

Sandra Regina Scagliusi: Great experience with elastomers. Upgraded in recovering of rubbers, in general, specially dealing with butyl and halo-butyl rubbers (chlorine and bromine). She is deeply involved with irradiation, recycling, de-vulcanization, micro-wave. She developed a new process of rubbers recovering via radiation and mechanical shear. She has been dedicating in research toward environmental area in recycling of solid materials and elastomers. Proved experience in research and quality control laboratories

Abstract:

Polymeric materials (plastics and rubbers) cover a continuously raising proportion of urban and industrial solid wastes discarded in landfills and consequently their impact on environment are more and more concern. Rubbers exhibit a very slow natural decomposition due to their chemical structure weather resistant as well to enzymatic degradation and to microorganisms. Rubber recovering is hampered by its insolubility caused by crosslinked structures. Besides, this tridimensional structure causes various problems for material recovering and reprocessing. Just 8% to 12% of polymeric residues are thermoplastic polymers; remaining are elastomers especially post consumption tires. It is relevant to emphasize that the crosslinking is essential for practical use of rubber and this process is worldwide known as vulcanizing process, discovered by North American Charles Goodyear. The implementation of new technologies in order to reduce polymeric residues, acceptable from the environmental viewpoint and at an effective cost proved to be a great problem due to inherent complexities for polymers reuse. Ionizing radiation has capacity to change structure and properties of polymeric materials. Butyl rubbers have been used in wide scale within a variety of applications such as tires spare-parts and diverse artifacts. Major effect of high energy photon, such as gamma rays in butyl and halo-butyl rubbers is the creation of free radicals accompanied by changes in mechanical properties. This work aims to the development of processes of controlled degradation (de-vulcanizing) of butyl rubber in order to characterize their availability for modification and changes of their properties. Experimental results obtained showed that butyl rubbers irradiated at 25 kGy and further sheared can be used as the starting point for mixtures with pristine rubber.

Laib khemissa

Batna university, Algeria

Title: The philosophical foundations and purposes of recycling

Biography:

Laib khemissa phd at contemporary philosophy in 2017 , Batna university, Magistère at cultural anthropology en 2006.

Abstract:

By presenting my experience in recycling of textile (through videos to reveal the aesthetic and economic value of recycling). my conference treats the recycling From a philosophical point of view as the treatise of Francois dagognet for example for which to take an interest in the waste philosophically is a way to oppose the consumer society which privileges the new one on the contrary the recycler sees in the waste not a kind of " Indetermination close to annihilation but a capacity for evolving resurrection and continuous creation and this could not be achieved without the revaluation of waste.Aristotle explains that he can not sustain a series of changes in the corporeal substance, which does not transform the nature of the substance. That is to say, it acquires or loses perfection without transforming itself into another substance. The movement expresses the dynamic dimension of reality, of things. It no longer accepts to see in the change of matter or form an absolute corruption. Things no longer become pure pure nor pure power, they are always in Becoming, in the possibility of passage from being in power to being in act Man by the continuous recycling of the same matter participates in the divine nature because by his creation he imitates the divine creation which made the world from eternal matter(hyllé). And by recycling matter participates in eternity. Unlike the perceptive of Francis Dagognet on Aristotle I affirm that matter never ceases to disappear as confirmed by Dagonet but never ceases to pass into creative works and I find that Aristotle does not join here the Platonic doctrines that misunderstood The matter and sees that it is philosophy alone that diverts us from the "waste" and from what they imply, and that curiously, the productive technique, the old as well as the current, participates in this aversion, so much we are everywhere Desiring the incorruptible and especially the shining (the back of the scrap). Recycling contradicts this idealism concretely and economically on the one hand and slows down on the other hand the liquid consumption of which the analyzes of ZYGMUNT BAUMAN alert us and the negative economic and moral consequences resulting from this type of desire of consumption.

Jonathan Cocker

Baker & McKenzie LLP, USA

Title: North America’s First IPR Will Create New Waste Diversion Opportunities

Biography:

Jonathan Cocker heads the Firm’s Environment & Environmental Markets Practice Group in Toronto, where he also serves as chair of the Pro Bono Committee. He authored the Global Climate Change Law Guide, and has worked with the Management Board Secretariat of the Government of Ontario. Mr. Cocker has represented a wide range of clients before various administrative boards, the Superior Court of Justice and the Federal Court of Canada, among others.

Abstract:

Industry-Funded Organizers to be Disbanded Currently, each province designates "Industry-Funded Organizations" or IFOs to enlist and coordinate the waste management activities of all of waste diversion participants, including the producers, haulers, recoverors, processors and reusers. These IFOs allocate volumes, set fee structures, rate performance and conduct auditing and performance assessments by all the regulated parties. The results have been viewed as inefficient, costly and creating uncertainty as a barrier to long-term investment and innovation. A call for market forces to dictate waste diversion management has led Ontario to commence disbanding the IFOs and placing the obligations for waste diversion (over a growing range of products/waste streams) back upon the producers/first importers/brand owners with little obligation other than diversion itself. Waste Management "Wild West" in Need of Diversion Expertise / Solutions It is anticipated that the producers will be seeking any number of solutions to discharge their IPR responsibilities for their substantial volumes of regulated waste. IPR only mandates the diversion of waste, but leaves open a variety of recovery and reutilization options previously precluded by the IFOs, but now made possible by the shift to market forces. Producers and related industry parties will be seeking environmentally-sound, yet market savvy strategies for their waste streams and, as North America's first IPR program, the experience and expertise from the European Union and elsewhere is highly valued in giving producers the assurance that waste diversion and environmental compliance will be achieved. As the IPR model will be replicated elsewhere in North America, the current Ontario model offers waste management participants with a rare opportunity to define the future. This paper will look at the opportunities that a transition to IPR will mean for the waste management industry and their diversion strategies across various regulated waste streams in North America.

Rusnam

Andalas University, Padang, Indonesia

Title: The Ability of Water Plants to Reduce the Level of Mercury Pollution in Water Quality for Irrigation

Biography:

Rusnam is a lecturer in the department of Agrilcultural Engineering Faculty of Agircultural Technology, Andalas University, Indonesia. His latest work is as a researcher in the fields soil and water engineering. His currents research is about related to agricultural water quality in the area of West Sumatera province, Indonesia. He is now teaching some subjects such as hidrology, soil and water conservation and environmental science.

Abstract:

This research was conducted on July – October 2013 about a mercury analysis which has been performed in Environmental Engineering Laboratory of Engineering Faculty, Andalas University. The level of mercury that is permitted by Government Regulation Republic Indonesia No. 82 of 2001 at the fourth grade for water is at 0.005 mg/l. In that analysis, mercury contents with 0.020169 mg/l at irrigated areas in Batang Hari River. This research aims to find out the ability of water lilies (Salvinia molesta), wood lettuce (Pistia stratiotes), and water hyacinth (Eichhornia crassipes) to decrease the content of water level. This research used experimental methods and the initial content of heavy metals mercury (Hg) by using 0.02 mg/L, 0.06 mg/L, and 0.1 mg/L. The results at decreasing concentrations of heavy metals mercury will be compared with the quality standard of heavy metal mercury at the fourth grade of water. The result showed that water lilies (Salvinia molesta), wood lettuce (Pistia stratiotes), and water hyacinth (Eichhornia crassipes) were able to fix the water quality for irrigation which contaminated heavy metal (Hg). Then, mercury concentration reached a quality standard for irrigation at early concentration 0.02 mg/L during the 15 days and at early concentration 0.1 mg/L during 35 days. From the analysis, it was found that Water hyacinth (Eichhornia crassipes) is the best plant to decrease the concentration of heavy metals mercury.

Ratnadip Bhoi

L. D. College Of Engineering, India

Title: Comparisons Physical Properties Between Concrete Paver Vs Rubber Cement Composite Paver

Biography:

Abstract:

The objective of this research paper is to study about the waste tyre crumb rubber granules as a partially concrete replacement by different percentage of facing layer thickness and without facing layer in the production of rubber cement composite paver block. The physical properties of RCCRP compressive strength, flexural strength, abrasion strength density, and water absorption testing by the IS 15658:2006 method. This all physical properties are depending upon the ratio of crumb rubber uses. The result showed that the with facing layer at 15 mm, 25 mm,totally rubberized and without facing layer had little effect on compressive strength, flexural strength and abrasion resistance properties. The absorption of water is also important for the service life of the product. The crumb rubber paver block also performed quite well in both compressive strength and abrasion resistance. The rubber cement composite paver block is suitable for nonstructural purpose such as lightweight, easily installation for the walkway, sidewalk and playing area application.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

Peter Tumwet Cherop

Durban University of Technology, South Africa

Title: Kinetics of granulated scrap tyre pyrolysis via thermogravimetry

Biography:

Peter Cherop is a Doctorate student in the Department of chemical engineering at Durban University of Technology. He holds a Master’s degree in chemical engineering from D.I. Mendeleyev University of Chemical Technology. He has expertise in process control, optimisation and pollution control and has previously worked in the cement manufacturing industry as a process engineer. He has experience in teaching and research having worked as tutor and researcher in institutions of higher learning. His key areas of interest are waste management and environmental pollution control.

Abstract:

The global consumption of tyres has increased over the years. However a very small percentage of the total mass of waste tyres can be recycled or reused for other applications. Land-filling has been considered an option to address the problem of scrap tyres. However, large space is required and the reusable resources are wasted. This therefore has led to environmental and economic problem of the disposal of the huge mass of scrap tyres. Scrap tyre pyrolysis, which is basically the thermal decomposition in an oxygen-free atmosphere, can be potentially involved with the recovery of both energy and material. Thermogravimetric analysis (TGA) and derivative thermogravimetry (DTG) are the techniques commonly used to measure the mass loss kinetics associated with the vaporisation of materials during pyrolysis. Understanding the kinetics of pyrolysis is important in the optimisation design of industrial scale scrap tyre recycling. The purpose of this study was to determine the thermal degradation kinetics of scrap tyres by TGA/DTG, and to compare the apparent activation energy (Ea) and the pre-exponential factor (A) values calculated using the Arrhenius, Coats–Redfern and Flynn-Wall-Ozawa methods. The experiments were conducted under a nitrogen atmosphere and a temperature range of 20°C to 600°C at different heating rates. The thermal decomposition started at an average temperature of 240°C and was complete at 480°C for the four heating rates. Results indicate that higher heating rates lead to greater mass losses. The average mass loss was 63.64 wt. %. The mean Ea values obtained by the different model free methods used were similar. However there was a variation in the pre-exponential factor values.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

N. Dakhili

Iran University of Science and Technology, Iran

Title: Chloride removal from the secondary source of zinc

Biography:

Nafiseh Dakhili has completed her Master at the age of 25 years from Iran University of Science and Technology with Thesis in Subject: Recovery of Zinc from the Final Slag of Steel’s Galvanizing Process by Pyro and Hydro Metallurgical Treatments and with GPA: 15.03 (out of 20). Then she works as Commercial Manager at Faragostar Altoon production and Commerce Company. She has 6 papers which presented at international conferences.

Abstract:

Zinc containing wastes/secondary's such as zinc ash, dross, flue dusts, sludge, residue etc. are generated in various chemical and metallurgical industries. The materials contain different level of impurities depending on the source. If zinc content material, like zinc ash and zinc slag, contains various amounts of chlorides like zinc chloride, zinc oxy-chloride, which comes from ammonium chloride and other chloride fluxes used by galvanizers, the chloride content has to be removed for the evaluation of this secondary resource for recovery as zinc metal or zinc oxide. The results (of the galvanizing slag’s treating that left after some pyrometallurgical presses) indicate that roasting at 800 °C for 30 min, followed by alkali washing treatment, at 70 °C for 45 min by 1/6 solid/liquid ratio and 1.5 times the stochiometric amount, will useful for chloride removal with 94% efficiency.

- Agricultural Waste Recycling | Circulatory Economy | E-waste Management | Metal and Plastic Recycling | Recycling Market | Thermal Waste Recovery

Session Introduction

Md Abdul Jalil

Bangladesh University of Engineering and Technology, Bangladesh

Title: Up-gradation of Matuail Solid Waste Disposal Site in Bangladesh to a Sanitary Landfill

Biography:

Md Abdul Jalil is a Professor of Civil Engineering Department at Bangladesh University of Engineering & Technology (BUET), Dhaka, Bangladesh. He received his BSc in Civil Engineering in 1986 from BUET. He obtained his MSc in Civil Engineering in 1988 from the same university. He received his PhD in Civil Engineering in 1993 from Tokyo University, Japan under ADB Scholarship. He conducted Post-doctoral research on Water Management in Loughborough University, UK under Commonwealth Fellowship. He was appointed as a Lecturer in the Department of Civil Engineering of BUET in 1986. He was promoted to the post of Assistant Professor in 1989. He became Associate Professor in 1996 and Professor in 2001. He has published over 36 papers upto now. His current research areas are biogas generation from solid wastes, water and wastewater treatment technologies, and rain water harvesing. He also works as a Consultant and completed over 45 important national development projects.

Abstract:

From the very beginning, Matuail landfill site was being used for crude dumping of solid waste of Dhaka City. Dhaka City Corporation decided to improve the dump site to a sanitary landfill and to design a new sanitary landfill at the acquired land adjacent to this site. A detail soil exploration was carried out and significant variation in soil strata was identified. A clay layer of 7.8–45 m was found having permeability in the order of 10-5 to 10-7 mm/s. The leachate of the landfill contained a number of pollutants in very high concentrations. Analysis of a water sample from a nearby tubewell revealed that a few parameters exceeded the drinking water quality standards. The pre-project environmental condition of the landfill site had the usual characteristics of an open dump site - filthy, smelly, and breeding ground of flies and mosquitoes. Oozing out leachate caused flooding of roads during rainy days and surface water pollution around the landfill site. Groundwater pollution potential was found to be very low. Local drainage congestion, filthy environment, breeding of flies and mosquito, obnoxious odor in the surrounding, fire hazards, air and noise pollution were some of the potential adverse environmental impacts during construction and operation phases of the landfill. Occupational health and safety of the workers at the landfill site including the waste pickers were of great concerns. Collection, treatment and safe disposal of excess leachate from the landfill site were given top priority to mitigate possible impacts on environment. Storm water drainage system was constructed around the landfill for efficient drainage of rainwater away from the landfill site. The peripheral slope was covered with thick clay layer. The decomposable fresh waste in each cell was covered by stabilized solid waste from the landfill site. A semi-aerobic system was installed to prevent accumulation of gases in the landfill. An effective environmental monitoring program was developed. The important landfill facilities of Matuail sanitary landfill were embankments, roads, platforms, storm water drainage system, leachate collection system, semi-aerobic system of waste stabilization, leachate treatment system, control building, weighbridge, car wash pool, flood light system, electrical sub-station and water supply and sanitation systems. Laboratory studies were conducted to determine design parameters to treat the leachate in aerated lagoons. The lagoons were designed as plug flow reactor. Sludge and treated effluent recycling to the waste dump was proposed as the disposal option. The construction of working road was started first, followed by new embankments, the civil structures in the control area, the flood lighting system, the drainage systems, roadway and platform, semi-aerobic system and finally the leachate treatment system. The major problems faced during the construction phase were related to working road, temporary platform, drainage system, new embankments and permanent platforms. The most severe problem was the failure of the new embankments at a number of sections. All these problems were solved by a critical analysis of each site specific problem and suggesting appropriate solution. As a result, the project was implemented successfully.

Muscolo Adele

Mediterranea University, Italy

Title: Comparison of composts obtained from olive pomace and vegetable residues as alternative to synthetic fertilizers

Time : 11:10-11:35

Biography:

Muscolo Adele graduated in Biological Sciences (MSc), has completed her PhD in Food Science at the age of 26 years at the Policlinic Federico II University of Naples, Italy. In 1988 she started is professional carrier as researcher at “Mediterranea” University of Reggio Calabria where she is still working as Full Professor in soil chemistry and ecology. Since 1990 she is reviewer for International Scientific Journals and since 2008 she is evaluator of projects for European Community, International Funding Research Agencies and Italian and Foreign Research Ministeries. She is chair of many Regional, National and International research projects.. She is examiner of international PhD dissertation. She published more than 180 papers in international journals with IF and has been serving as an editorial board member of many International Journals. She is Associate Editor for JFR.

Abstract:

In recent years, research is increasingly oriented towards the use of agronomic techniques to improve the productivity in terms of quantity and quality of products, promoting the conservation of natural resources, protecting the soil resource and reducing the environmental impact. In Mediterranean area, crop production is suffering mainly for the loss of soil fertility and the consequent massive use of expensive macro- and micro-nutrient inputs for which agriculture is almost totally dependent on imported products or on fertilizers produced with expensive industrial processes, which generates greenhouse gases (GHGs). In view of the above considerations, this study was conducted to determine the chemical characteristics of six composts obtained with organic wastes from different sources. The fertilizer power was assessed on soil and plant. Waste characteristics influenced the chemical properties of the compost much more than composting process. The obtained compost had a positive effects on soil with an increase in soil organic matter, nutrients, MBC, and bacterial and fungal population that differed in respect to compost features. The best result on soil, was obtained by using the compost produced with a mix of broadleaf vegetables. Regarding crop productivity, the data showed a specificity between crop and type of compost used.

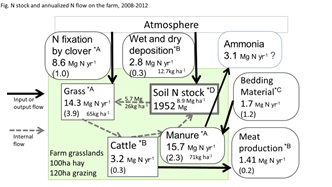

Masayuki HOJITO

Kitasato University, Japan

Title: Nitrogen Flow on an Organically Managed Beef Farm in Hokkaido, Japan

Time : 11:35-12:00

Biography:

Masayuki HOJITO is a professor of Kitasato Univsersity, Towada, Aomori, Japan. His scientific career over 30 years has been based on Soil Science. He is coordinating the University Farm: The Yakumo Experimental Farm is located in southern Hokkaido and it is a unique practical farm, which has established a self-sufficient resource-recycling system. Fertilizers, chemicals or feeds from outside are completely restricted. The farm produces the Kitasato Yakumo Beef (with a Registered trade name) that is the first certified organic beef in Japan. The crucial factor in this process is the management of white clover. Chemical fertilizers are not used and only well-composted cow manure is applied onto the clover-mixed grasslands. Utilizing this method it has been demonstrated that organic and safe beef can be produced using a 370-hectare natural ecosystem without causing any environmental pollution. In essence this system demonstrates that solar energy produces beef.

Abstract: